End-to-End Calibration using Live Measurement Data

Physical end-to-end calibration and adjustment ensures accurate data collection by thoroughly inspecting the measurement system components, allowing for early detection and correction of potential issues.

Calibration procedure

-

To load the configuration of the connected DAQ system into the project window, click Read or open an existing project that matches the connected hardware configuration.

-

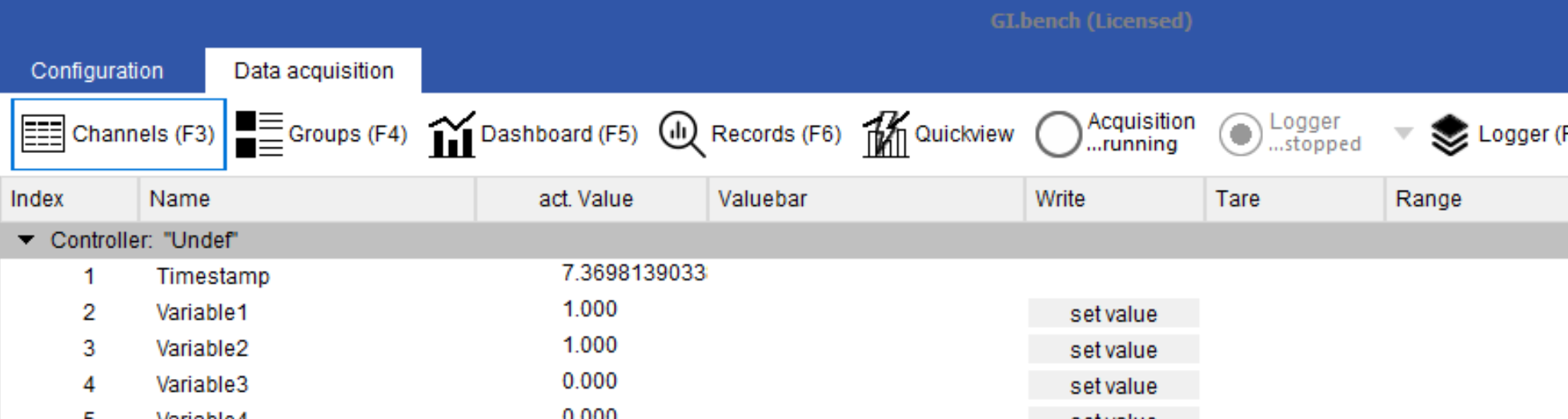

Next, navigate to the Data Acquisition tab to initiate the acquisition process.

-

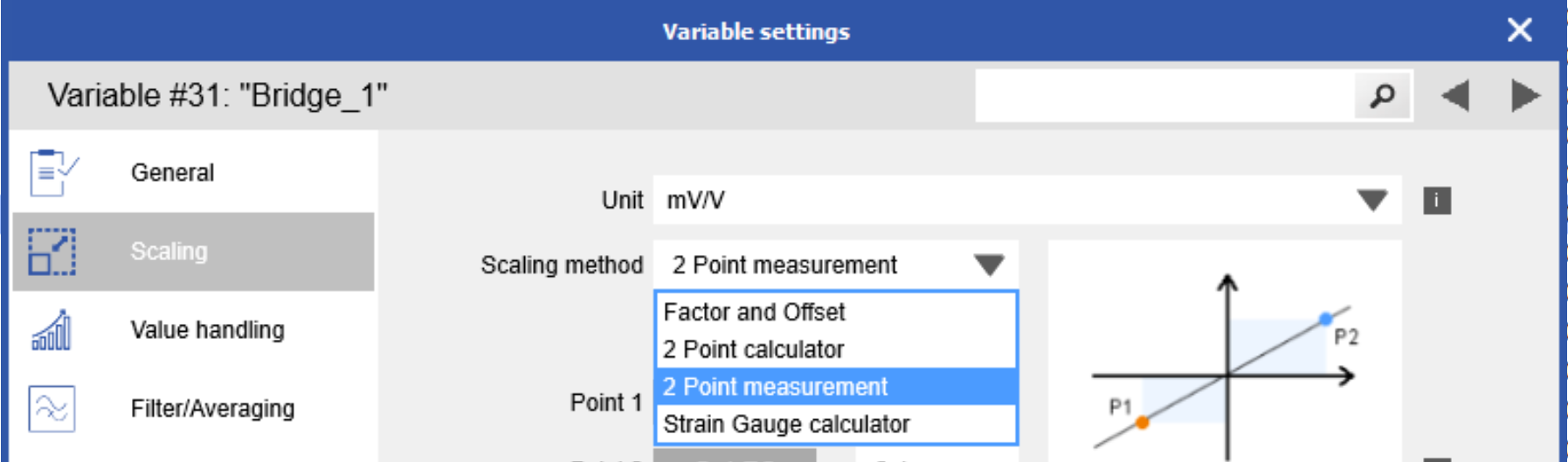

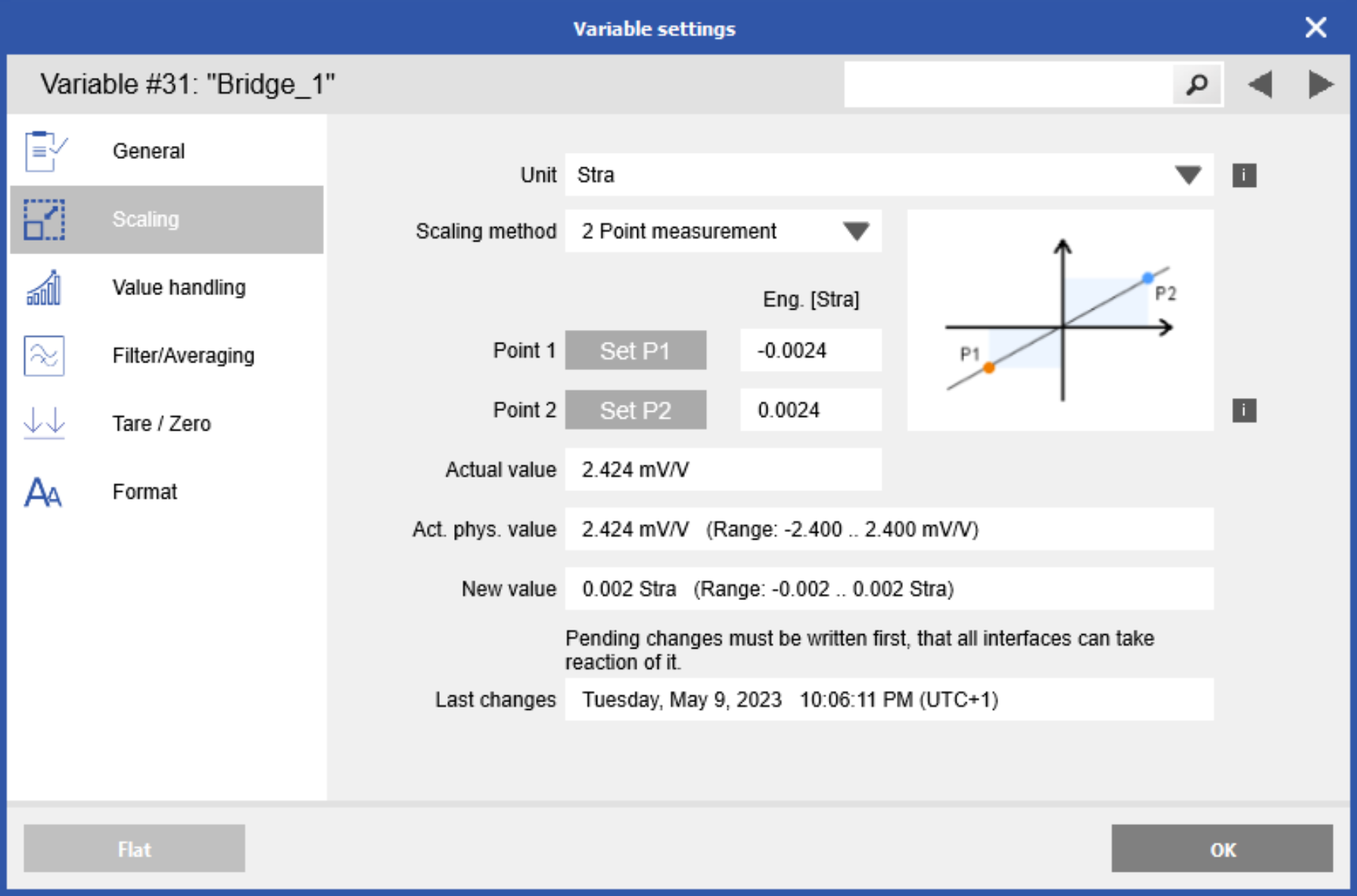

You can either right-click and select Edit variable from either the data acquisition or configuration tab to access the variable settings window.

-

From there, you can choose or input the desired engineering unit for scaling purposes.

-

In the scaling section, you'll find a drop-down list for the scaling method, which now includes the option for 2 Point Measurement.

-

Assign a value to the signal and then click Set P1. Proceed by applying the next value and clicking Set P2. This process establishes a two-point scaling relationship between the physical and engineering units. All data points will be linearized according to this established line.

-

Click OK when complete, then go to Configuration > Write to write updates to the DAQ system.