Understanding the Gantner Instruments Calibration Report

Explanation about measurement uncertainty, tolerance, deviation, and error.

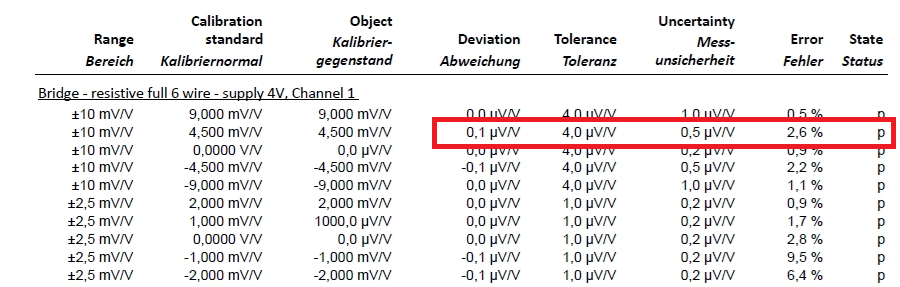

All measurement modules from Gantner Instruments undergo precise factory calibration to ensure exceptional accuracy. Each unit is accompanied by a calibration report that details the calibration results, giving users confidence in the reliability and performance of their equipment. This article provides an in-depth explanation of the specifications included in the calibration report.

Uncertainty

During calibration, Gantner Instruments performs comparative measurements between the measurement module and high-precision reference devices, which serve as the calibration standard. These reference devices have their own defined level of accuracy, necessitating the inclusion of calibration reference measurement uncertainty in the process. In practical terms, this means that all measured values from the measurement modules may vary slightly around the reference point. The uncertainty is calculated using the principles of Gaussian error propagation (GEP).

Deviation

The deviation represents the variance between the measurement module and the calibration reference. Based on its position within the defined upper and lower tolerance limits, the result is categorized as:

- Pass: The measurement result falls within the specified tolerance range, even when extended by half of the uncertainty interval.

- Probably pass: The measurement result falls within the specified tolerance range but by a margin smaller than half of the uncertainty interval. Therefore, compliance cannot be definitively stated.

- Probably fail: The measurement result is outside the stated tolerance, but by a margin less than half of the uncertainty interval. It is therefor not possible to state compliance.

- Fail: The measurement result is outside the stated tolerance, even when extended by half of the uncertainty interval.

Tolerance

The tolerance defines the allowable range within which the deviation of a measurement result, including its uncertainty, must fall.

Error

The error is the percentage value of the deviation relative to the tolerance, as illustrated in the example calibration report below.

Note: 0.1 µV/V represents approximately 2.6% of 4.0 µV/V. Why is it 2.6% and not 2.5%? This is due to the rounding of the deviation value.