Frequency Measurement using the Chronos Method

The advantages of using the Chronos method for frequency measurement explained.

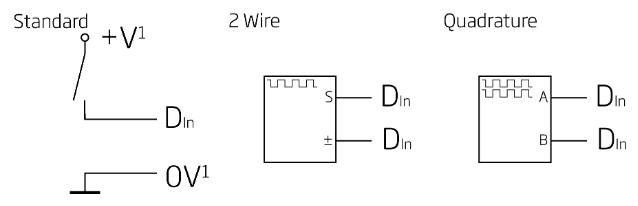

In addition to state, PWM, and counter measurements, the Q.series A109, D101, and D107 digital input modules offer three types of frequency measurement:

- Standard single-ended, 4-channel frequency input.

- Standard 2-wire, 4-channel frequency input, including direction.

- Quadrature 2-wire, 4-channel frequency input or 2-channel signal A and B

with 90° phase shift.

Quadrature inputs are available on A109 and D101 modules only.

The Chronos method

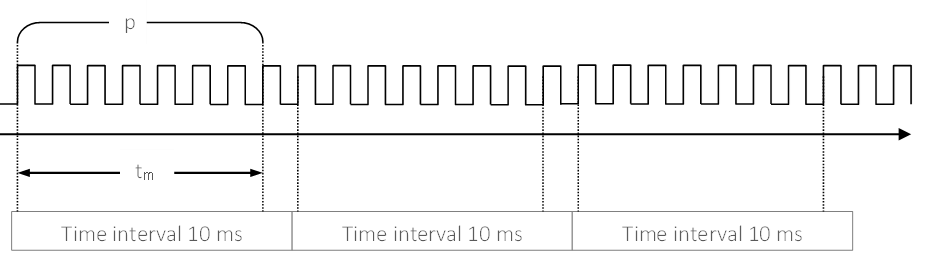

The Chronos method allows for accurate frequency measurement of both low and high frequencies. This method combines the advantages of time measurement and pulse counting, where the pulses within a specific time interval are counted. To achieve the highest accuracy, we use not the pre-set time interval, but rather the time between the first and the last positive edge to calculate the frequency.

With a standard clock frequency of 48 MHz, one count represents 20.8 ns. This resolution allows us to detect the frequency independently of the input frequency itself. The selectable time interval ranges from 0.001 s to 10 s, and the maximum input frequency is 1 MHz.

For instance, with an input frequency of 715.238 Hz, there will be 8 positive edges, or 7 periods, within a single time interval of 10 ms. The time elapsed from the first to the last positive edge is precisely 9.78695 ms (with a resolution of 20.8 ns). The calculated frequency is then determined as 7 / 9.78695 ms x 1000 = 715.238 Hz.

The Chronos method offers several advantages:

- It requires only one pulse for precise frequency measurement.

- It has an integrating character, reducing measurement signal noise.

- Measured values are divided into fixed time intervals.

- The time interval is user-selectable.

- The method is applicable for continuous measurement from 1 Hz to 1 MHz.

For very low frequencies where no edges are detected within a selected time interval (e.g., 100 ms), the method automatically extends the interval until the next pulse occurs, allowing measurement even for very low frequencies. The edge-to-edge time is measured with a resolution of 20.8 ns, applicable to input frequencies down to 0.5 Hz.

If the frequency suddenly stops, the measured value gradually ramps down to zero within 2 seconds using an exponential function, eliminating abrupt jumps.

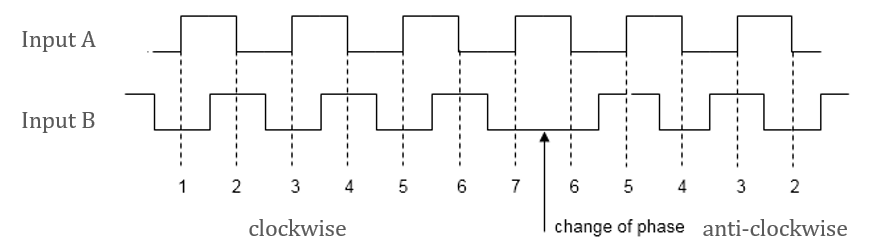

The quadrature function requires a sensor that provides two signals with a 90° phase shift. This method has the advantage of not detecting external disturbances like torsional vibrations as a frequency. Additionally, the phase shift can be used to determine the direction of rotation.

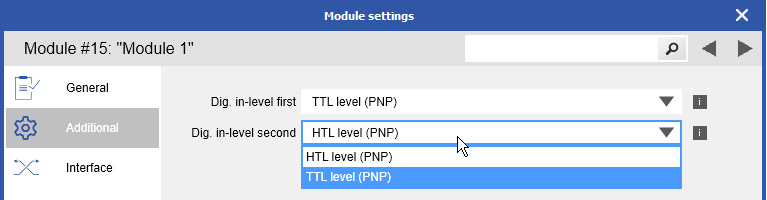

Input configuration

To adjust the input stages to the sensor, you can choose from two selectable input levels:

- TTL (logic 0 (LOW) <0.8 VDC / logic 1 (HIGH) >2.0 VDC)

- HTL acc. EN61131-2 (logic 0 (LOW) -3 to +5 VDC / logic 1 (HIGH) +10 to +30 VDC)

The D107 module features user-configurable thresholds, ranging from 0 to +26 VDC for single-ended inputs and -20 to +20 VDC for differential inputs.

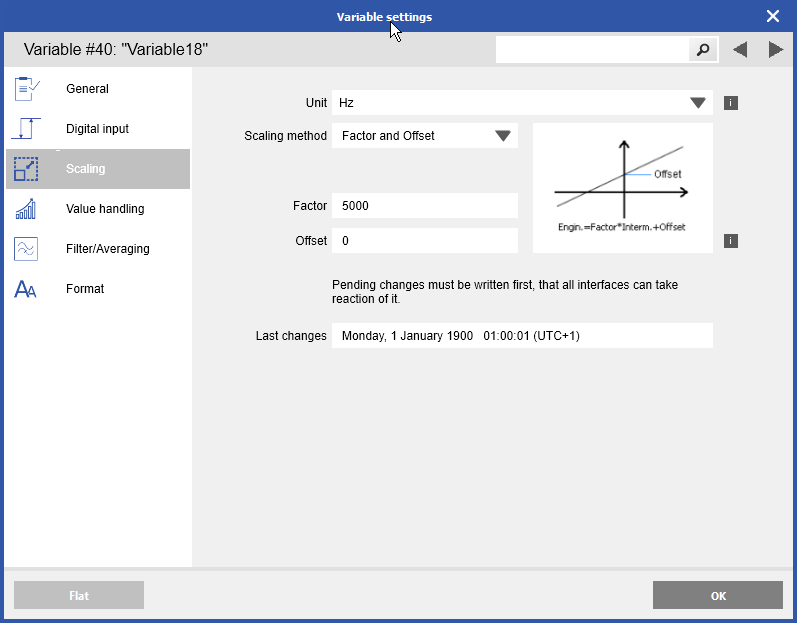

To obtain the measurement value in calibrated engineering units, the software provides a scaling function: